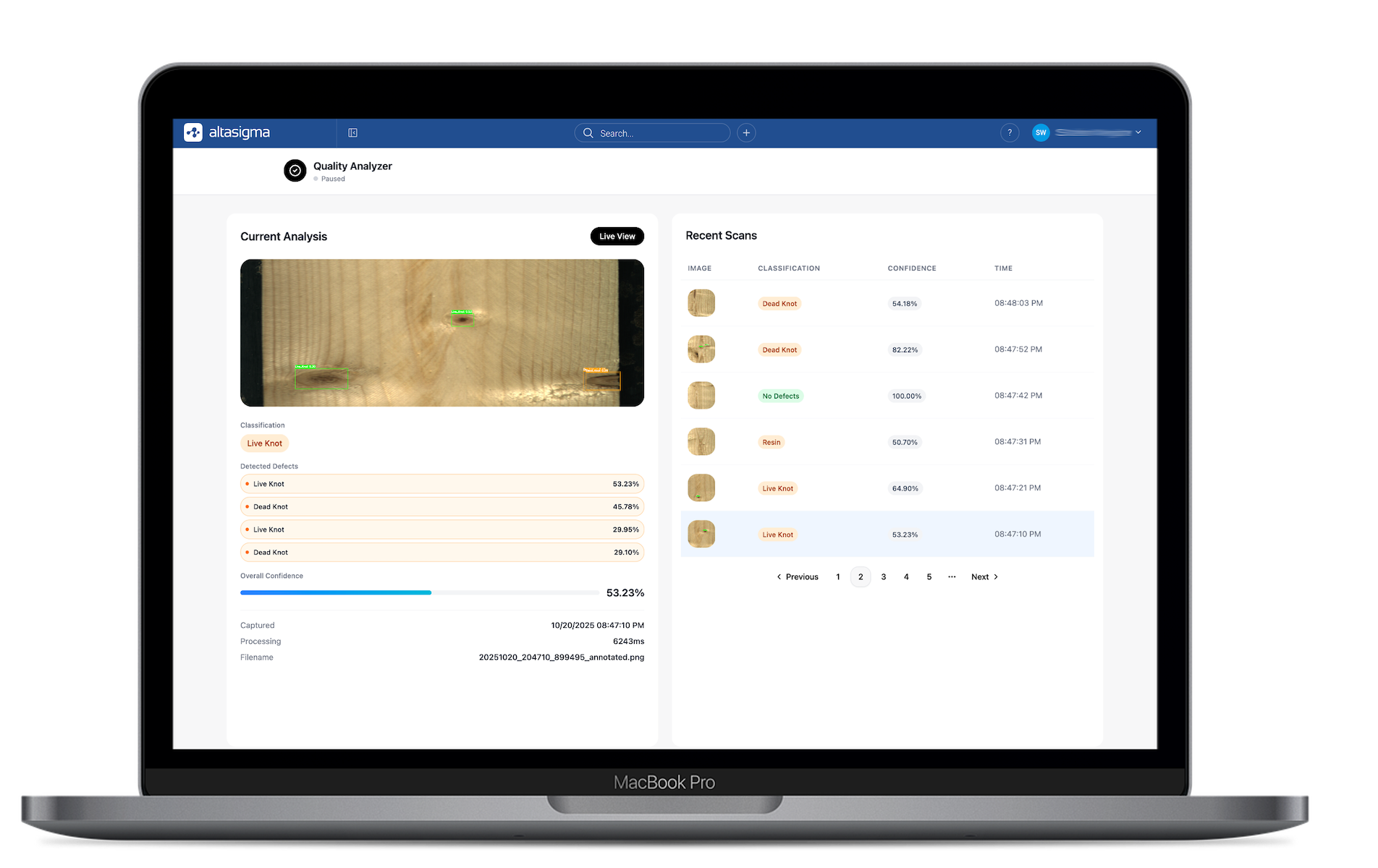

Wood Quality AnalyzerRedefining Wood Quality – Powered by AI-Driven Surface Analysis.

Detect Wood Defects Before Processing Begins.

The Wood Quality Analyzer sets new standards in wood processing. Our AI solution detects knots, mold, and other surface defects in real time, enabling 100% quality inspection of every wood piece - for maximum efficiency and sustainability.

Funktionalitäten

Advanced Analysis Methods: Harnesses deep learning, image processing, and anomaly detection to accurately identify surface defects on wood.

Automated Defect Analysis with XAI: Delivers transparent, explainable AI results for easy interpretation and maximum trust in the system.

Drift Detection: Identifies subtle changes in wood surfaces early, enabling proactive adjustments to production processes.

Digital Quality Verification Generates a complete digital quality profile for every individual wood piece — in real time.

100% Traceability: Each analyzed wood piece receives a digital defect and quality report, fully traceable across the entire supply chain for total transparency and control.

High-Frequency Data Processing: Processes real-time data streams to enable immediate, actionable quality assessments.

Our solutions harness enterprise-grade AI capabilities that truly make a difference

AI Model ManagementAI Models – Custom-Trained. Automatically Optimized. Always Up-to-Date.

Integriertes Data LakehousePlug & Play for Your Data – Compatible. Flexible. Fully Integrated.

REST APIAI-as-a-Service – Open. Extensible. Ready to Connect.

Compliance by DesignLegally Compliant. Transparent. 100% Aligned with the EU AI Act.

Wood Quality Analyzer – Key Benefits at a Glance

0%

Surface inspection powered by automated AI analysis

+0%

Faster quality checks compared to manual inspection

0%

Traceability for every component — from inspection to delivery

Unique Selling Points

01

Precision-Tuned AI AlgorithmsCustom-built computer vision models ensure accurate detection of knots, mold, and other surface defects in wood.

02

Transparent AI ResultsClear explanations and visual insights make AI-driven defect detection fully understandable and trustworthy.

03

Adaptive Process OptimizationAutomatically detects data shifts and continuously adjusts the AI for optimal performance in dynamic production environments.

04

Real-Time Quality ControlInstant detection and alerting of surface defects — directly on the production line for immediate action.

05

Digital Documentation & Full TraceabilityEach wood piece receives a detailed digital quality report, fully traceable throughout the entire supply chain.

06

Scalable by DesignFrom pilot projects to full-scale enterprise deployment — the solution evolves with your operational needs.

Discover more Smart Factory Solutions from AltaSigma

Predictive Maintenance

Our Predictive Maintenance solution identifies maintenance needs before failures occur – ensuring maximum asset availability and scheduled upkeep.

Predictive Quality

With Predictive Quality, you proactively safeguard your product quality – through intelligent forecasting and automated optimization across the entire production line.

Adaptive Anomaly Detection

Adaptive Anomaly Detection ensures process reliability, detects deviations in real-time, and provides precise root cause analysis for dependable and stable manufacturing.Curious to learn more?

Discover how the Wood Quality Analyzer can revolutionize your quality control.