Predictive MaintenanceTransform your maintenance strategy with AI: accurate predictions, minimal downtime, and maximum operational efficiency.

Smarter Maintenance Starts Here – Predict Failures Before They Happen with AI-Powered Insights.

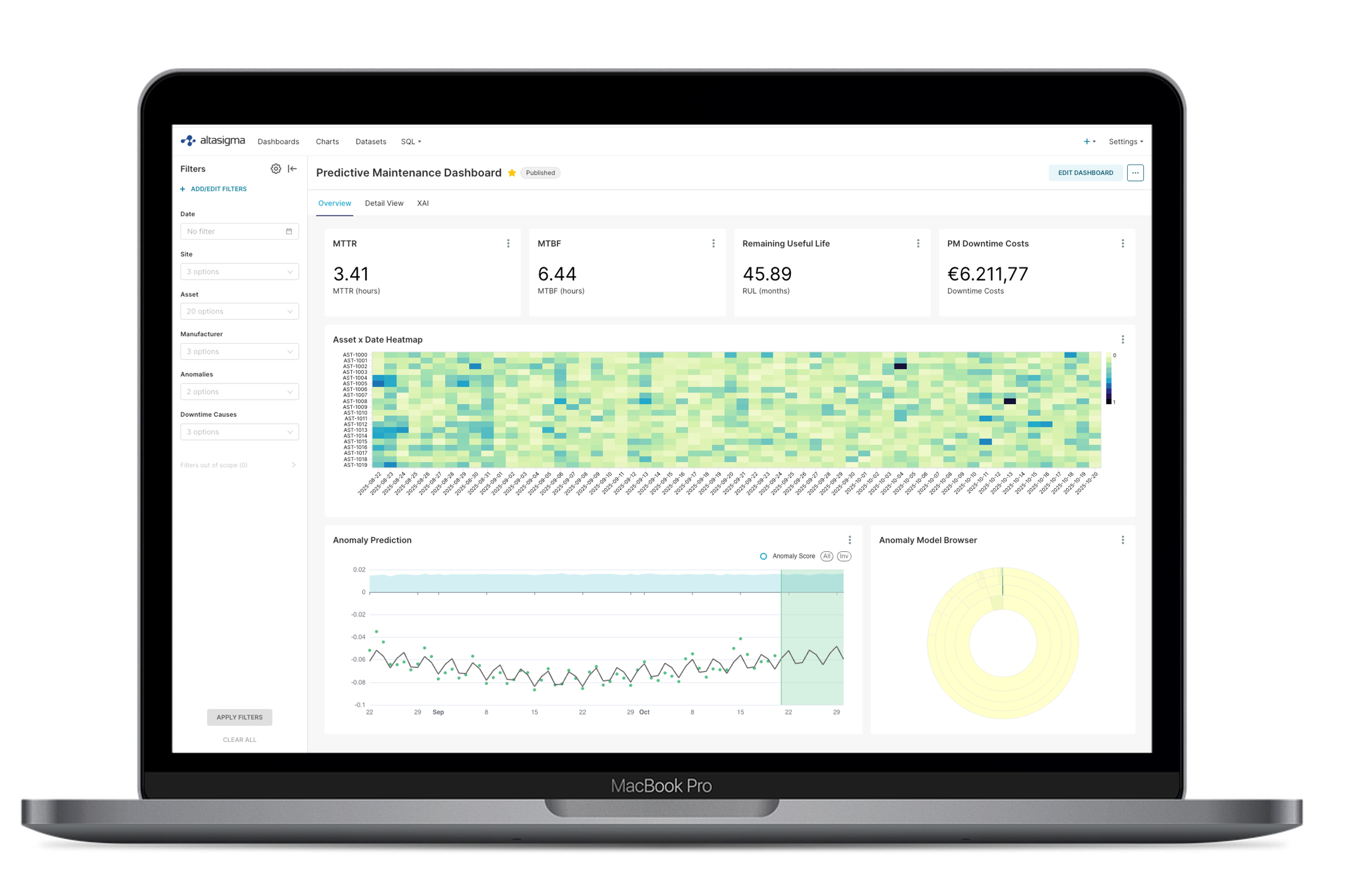

Our AI platform delivers tailored predictive maintenance solutions that minimize downtime and revolutionize maintenance processes. Benefit from the flexibility of our AI algorithms, ranging from anomaly detection to advanced remaining useful life (RUL) models.

Features

Diverse Algorithm Portfolio: Supports all leading predictive maintenance approaches—from advanced forecasting models to anomaly detection—to deliver the optimal solution tailored to your specific needs.

Accurate Remaining Useful Life (RUL) Predictions: Data-driven calculation of machine lifespans helps minimize unexpected downtime and enables precise, proactive maintenance planning.

Continuous Model Evaluation & Drift Detection: Ongoing monitoring detects performance drift early, ensuring your predictive models remain consistently accurate and reliable.

Automated Fault Analysis with Explainable AI (XAI): Leveraging explainable AI, fault diagnosis is automated for faster, transparent, and more effective problem resolution.

Seamless, Flexible Data Integration: Easily integrates data from internal and external sources—including PLCs, sensors, and ERP systems—via a powerful Data Lakehouse architecture.

Advanced Feature Engineering & Signal Processing: Supports comprehensive feature engineering and digital signal processing techniques (e.g., FFT, Wavelet) for in-depth analysis of high-frequency sensor data.

Our solutions harness enterprise-grade AI capabilities that truly make a difference

AI Model ManagementAI Models – Custom-Trained. Automatically Optimized. Always Up-to-Date.

Integrated Data LakehousePlug & Play for Your Data – Compatible. Flexible. Fully Integrated.

REST APIAI-as-a-Service – Open. Extensible. Ready to Connect.

Compliance by DesignLegally Compliant. Transparent. 100% Aligned with the EU AI Act.

Predictive Maintenance – Key Benefits at a Glance

+0%

faster fault analysis

-0%

fewer unexpected failures

-0%

reduced maintenance costs

Unique Selling Points

01

Algorithm Diversity for Perfect PrecisionWe move beyond one-size-fits-all solutions by offering a broad spectrum of algorithms—delivering tailored predictions optimized for every machine and data scenario.

02

Transparent AI Builds TrustWith Explainable AI (XAI), decision-making becomes clear and understandable—for engineering teams and regulatory compliance alike.

03

Plug-and-Play Data IntegrationOur platform seamlessly integrates into existing systems—from PLCs to ERP—without lengthy migrations or data loss.

04

Dynamic Model MonitoringEarly detection of model performance drift ensures consistently accurate forecasts through automatic self-adjustment.

05

Built for High-Frequency Data StreamsWhether vibration signals, current flows, or sensor impulses - our platform analyzes real-time data and delivers insights before issues arise.

06

Fully Industrial-Scale ReadyFrom a single production line to a global machine fleet, our platform scales effortlessly while maintaining peak performance—regardless of data volume or setup.

Discover more Smart Factory Solutions from AltaSigma

Process Mining

Our AI-powered Process Mining solution enables process discovery and real-time monitoring of process compliance – ensuring maximum transparency and efficiency.

Predictive Quality

With Predictive Quality, you proactively safeguard your product quality – through intelligent forecasting and automated optimization across the entire production line.

Adaptive Anomaly Detection

Adaptive Anomaly Detection ensures process reliability, detects deviations in real-time, and provides precise root cause analysis for dependable and stable manufacturing.Curious to learn more?

Unlock the power of AI to transform your maintenance strategy. Contact us now to learn how our tailored solutions can drive your business forward.