Adaptive Anomaly DetectionSpot the smallest deviations before they become a problem – with AI-powered Anomaly Detection.

Identify the unseen before it becomes an issue.

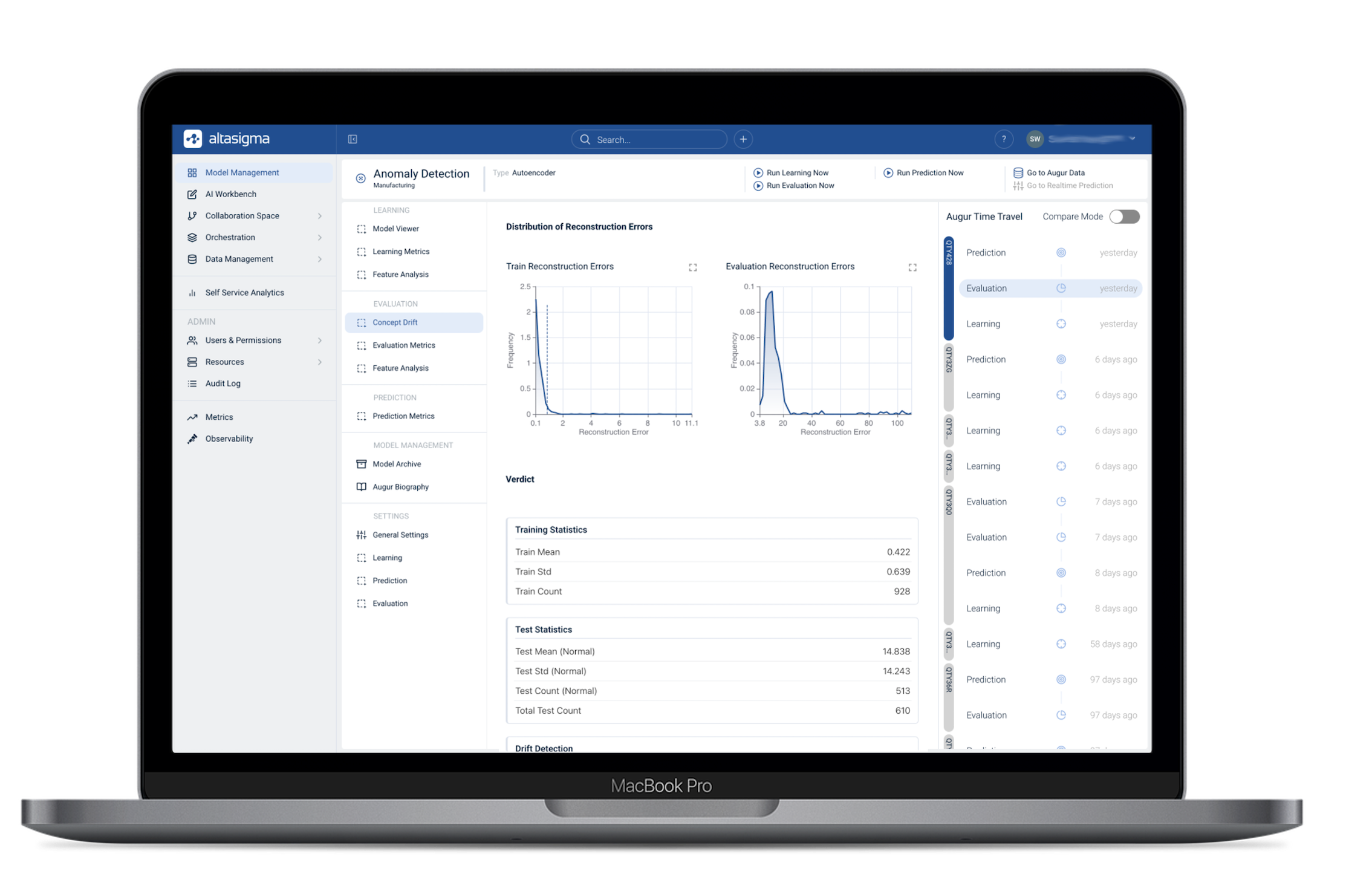

Adaptive Anomaly Detection detects even the smallest anomalies in production processes – automated, AI-driven, and in real time. This solution helps businesses identify process disruptions early, before they affect quality or availability, and provides transparent insights into causes and relationships through integrated Explainable AI (XAI).

Features

Comprehensive Algorithm Variety for Every Use Case Supports all relevant anomaly detection methods – from statistical techniques to deep learning.

Reliable anomaly detection in both continuous and discrete processes: Whether in continuous production or discrete assembly — our models detect deviations with precision across all process types.

Adaptive Model Selection: Combines and switches algorithms based on process and data behavior to ensure optimal performance.

Early Drift Detection: Identifies performance drift – both short-term effects and gradual changes over time.

Explainable AI (XAI) Included: Automatically provides visual and semantic explanations for detected anomalies, enabling quick root cause analysis.

Signal Processing & Feature Engineering: Handles high-frequency data using techniques like FFT, Wavelet, and more – including feature generation for advanced analytics.

Our solutions harness enterprise-grade AI capabilities that truly make a difference

AI Model ManagementAI Models – Custom-Trained. Automatically Optimized. Always Up-to-Date.

Integrated Data LakehousePlug & Play for Your Data – Compatible. Flexible. Fully Integrated.

REST APIAI-as-a-Service – Open. Extensible. Ready to Connect.

Compliance by DesignLegally Compliant. Transparent. 100% Aligned with the EU AI Act.

Adaptive Anomaly Detection – Key Benefits at a Glance

+0%

improved process quality

+0%

faster root cause analysis

0%

traceable and explainable results

Unique Selling Points

01

Detection of Hidden Process DeviationsIdentifies anomalies traditional systems miss – before they impact production.

02

Fast Deployment Without Complex Data PreparationOur AI learns directly from your production data – no labels required, ready to run in just days.

03

Modular and Scalable by DesignEasily integrates with other AltaSigma solutions like Process Mining, Predictive Maintenance, or Predictive Quality.

04

Automated Insights and VisualizationsDelivers instantly actionable insights – no manual analysis needed.

05

Real-Time Integration with Production SystemsDetects and reports anomalies in live production environments – with zero delay.

06

Fully Scalable Platform ArchitectureGrows with your needs – from single-line pilots to full-scale enterprise deployments.

Discover more Smart Factory Solutions from AltaSigma

Process Mining

Our AI-powered Process Mining solution enables process discovery and real-time monitoring of process compliance – ensuring maximum transparency and efficiency.

Predictive Maintenance

Our Predictive Maintenance solution identifies maintenance needs before failures occur – ensuring maximum asset availability and scheduled upkeep.

Predictive Quality

With Predictive Quality, you proactively safeguard your product quality – through intelligent forecasting and automated optimization across the entire production line.Curious to learn more?

Discover how Adaptive Anomaly Detection can transform your production processes. Schedule a personalized demo today and see the difference firsthand.